Quality Assurance

Apex Stainless Fasteners has been quality assured by Lloyd's Registered Quality Assurance (LRQA) since 1995. LRQA has certified that quality management systems at Apex are ISO9001:2015 compliant, which is applicable throughout all company, warehouse and manufacturing sites.

View the Company's certificate of approval here

Apex strives to ensure that only the highest quality products are sourced, with production processes that 100% comply with international standards. All product undergo thorough quality checks upon arrival into our warehouses. Good are clearly marked with relevant information, including standards, descriptions, grades and lot and heat numbers, in line with the Company's full traceability promise.

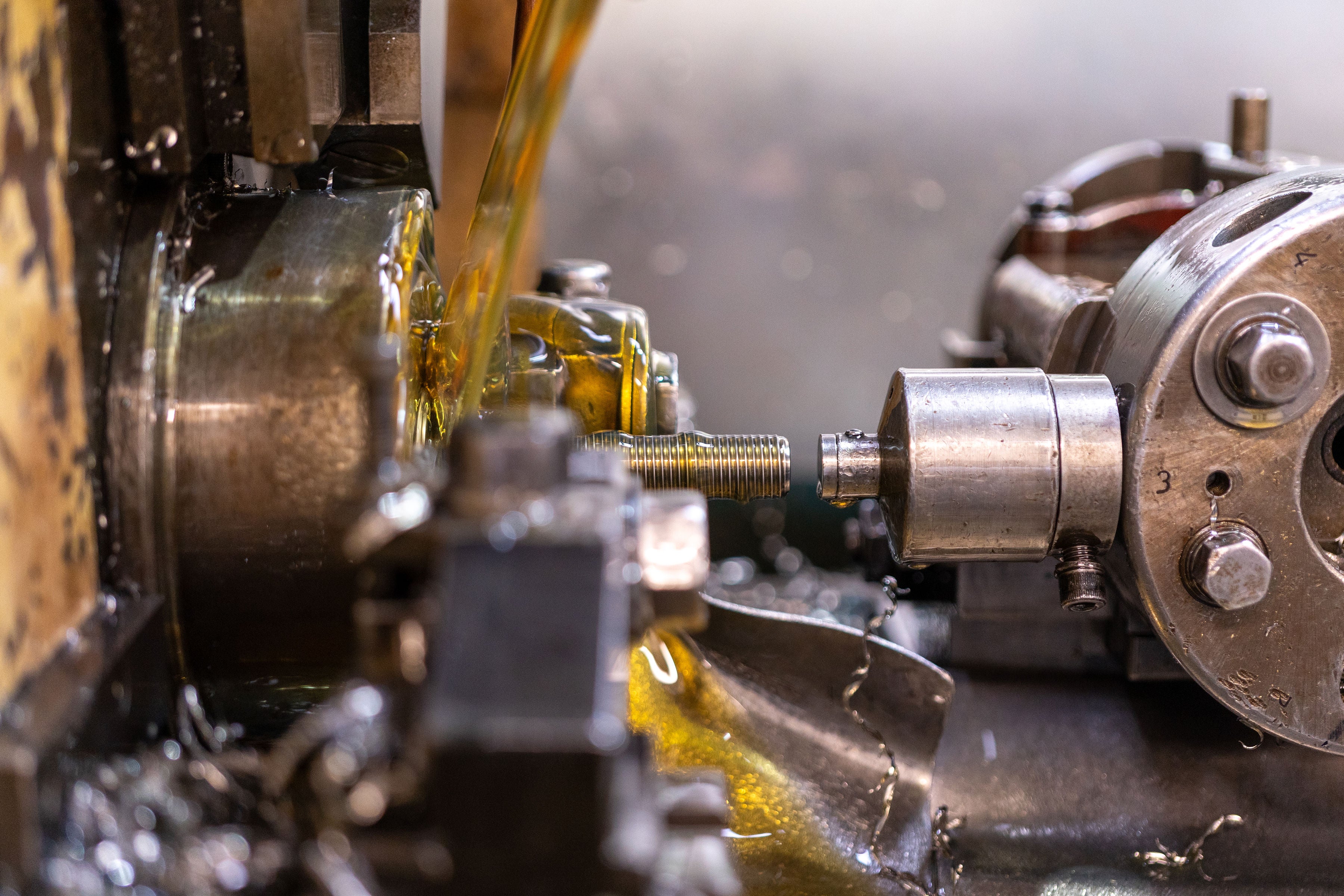

[Aerotight Manufacturing]

Certificates of conformity are available on request for all products.

Apex's manufacturing plant, Aerotight Manufacturing, conforms to the same high quality standards, with only the best raw materials used in production, with full mechanical and chemical certification. Optical Measuring AutoCAD is also used for production drawings.

The Company's quality process involves thorough inspection and testing for all in-house and off-site processes, complete with a final approval inspection to guarantee that al Apex manufactured parts meet strict quality standards.

To learn more, find Apex's Quality Policy here.