Manufacturing

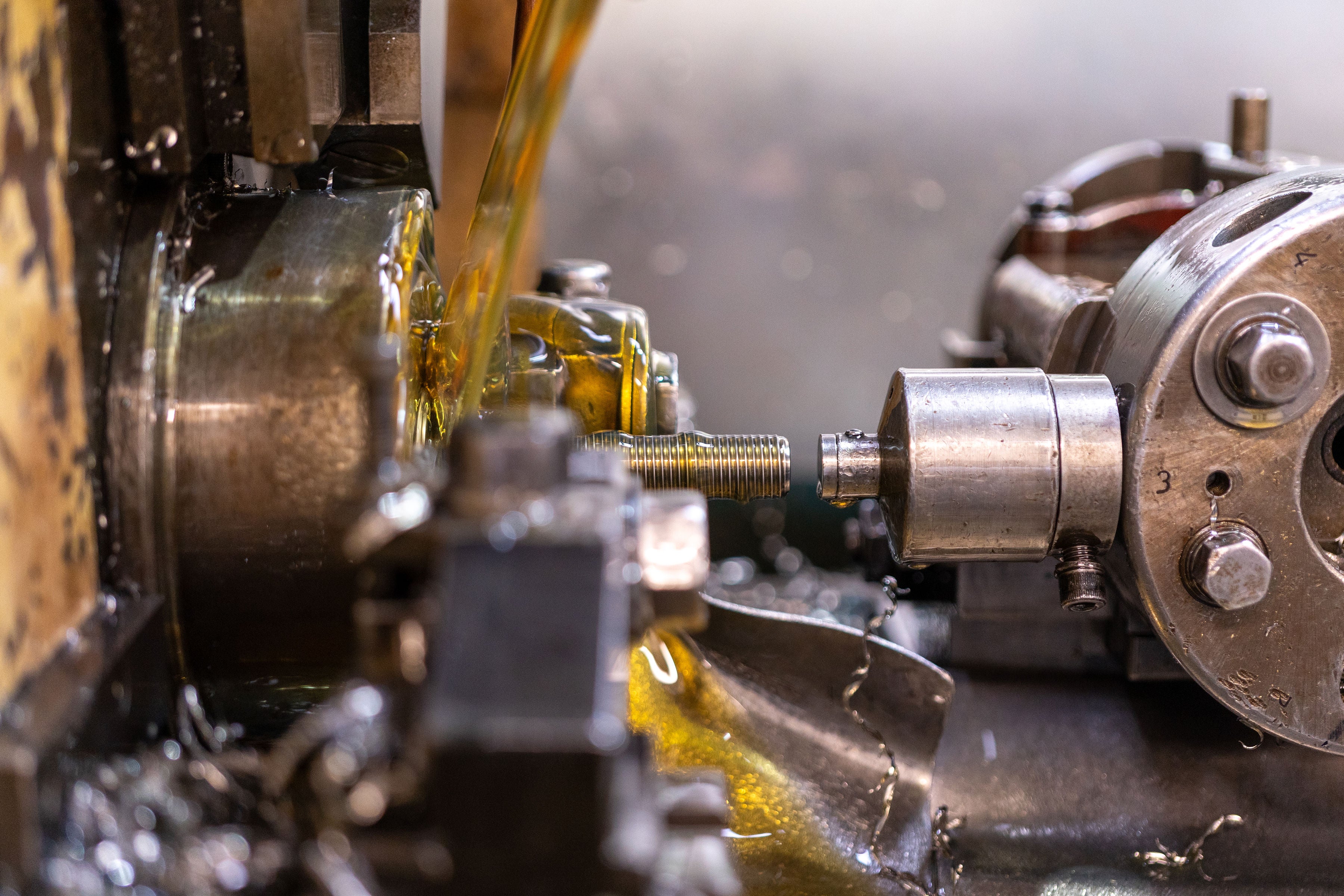

Apex Stainless Fasteners conducts in-house manufacturing at its manufacturing plant, Aerotight Manufacturing, based in Leicester.

The expert team produce the self-locking Aerotight nut, a highly durable nut with many industry applications, including anti-vandal technology and harsh weather conditions.

The nut is available to order in custom thicknesses, diameters, materials and finishes.

[Aerotight Manufacturing]

Special turned parts are also manufactured at Aerotight, according to customer drawings. Auto CAD technology is used to bring to life customer requests, available in customised size and finishes.

All manufacturing, included products, processes and systems are LRQA ISO9001:2015 quality assured.

To learn more download the Aerotight Brochure or contact us.